Despite cork's many applications, the natural cork stopper is the product derived from cork with the highest added value and which brings the greatest profits to the cork industry.

Throughout history, cork has been used by ancient civilizations, especially in the manufacture of boats and fishing equipment, footwear and construction, as well as to seal barrels (APCOR, 2015).

However, it was in the 18th century that the cork industry really began, when the French monk Dom Pierre Pérignon used natural cork as a champagne stopper for the first time. In the 20th century, the cork industry underwent a huge expansion, particularly due to the development of various cork-based agglomerates and the growing internationalization of wine consumption.

Today, there is a wide range of cork stoppers on the market adapted to each wine segment. Nevertheless, the cork industry continues to invest in product innovation, focused on improving its quality and on a product adapted to market trends and consumer needs.

Table 1 shows the different types of cork stoppers and their main characteristics.

Table 1. Characteristics of the different types of cork stoppers.

| Types of stoppers | |

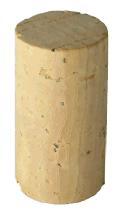

Natural corks |

Only the natural 100% cork stopper can ensure the perfect balance with the wine, promoting its evolution through numerous chemical processes. They are manufactured by drilling from a single piece of cork. Essential for quality wines. It can seal any type of wine. |

|

|

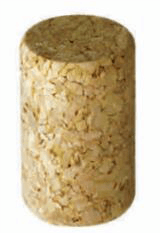

Natural cork stoppers with greater porosity. The pores are filled with cork powder resulting from the grinding of natural cork stoppers fixed with glues based on natural resin and natural rubber. They have a very homogeneous visual appearance and good mechanical characteristics. |

|

|

Made up of a dense body of agglomerated cork, with natural cork discs glued to one top, or both tops, with binders approved for use in products that will come into contact with food. It is chemically stable and mechanically resistant. |

|

|

Designed to seal champagne, sparkling wines and cider. Made from a body formed from agglomerated cork granules, to which 2 natural cork discs are applied on one of the tops. They have a larger diameter, which is essential to withstand the high pressures in sparkling wine bottles. |

|

|

Made from completely homogeneous granules of cork from by-products resulting from the production of natural stoppers by individual molding or extrusion. Used in low-priced, high-rotation wines. An economical solution to ensure a perfect seal for a shor period of time. |

|

|

A”Bartop” cork stopper with capsule made of wood, PVC, porcelain, metal, glass or other materials. Generally used in liqueur/generous wines or spirits. Easy to reuse - an important factor in bottles whose contents are not consumed all at once. |

At the end of the 20th century, cork stoppers were the target of accusations related to the "cork taint" present in wines. The "cork taint " is associated with the presence of cork contaminants with musty and musty aromas (Coque et al., 2006), with TCA (sgila for the chemical compound 2,4,6 - Trichloroanisole) considered to be the main culprit for this sensory defect. As a result, the cork market suffered with significant economic losses.

At the same time, new closures alternatives to cork have appeared on the market, making the situation of the cork industry worse and threatening the position of cork stoppers and natural cork on the market as closures of excellence.

Alternative closures include synthetic closures, screw caps, glass stoppers, etc.

Synthetic closures are inexpensive closures made from polymeric materials that mimic the natural appearance of cork, but with great homogeneity, making them visibly attractive. They are said to have a similar elasticity and appearance to cork stoppers and can even be used in conventional bottling systems.

The vast majority of synthetic closures also have the particularity of generating "pop" when extracted with a corkscrew, which is considered an argument in favor from a cultural point of view.

Screw caps are the most popular closures in the "war" against natural cork stoppers. They consist of an outer part made of an aluminum alloy and a liner inside with different layers of polymers that are in contact with the wines. There are 2 types of liner on the market: saran-tin and saranex. The main characteristic of saran-tin is its low permeability to gases, unlike saranex, which is more permeable to oxygen (O2).

The screw caps are uniform, very easy to open and maintain the highest levels of free sulphur dioxide (SO 2) in the wines. The glass stopper (Vinolok®) is used by many German and Austrian wine producers. It is inert, neutral, very effective as a closure, recyclable and aesthetically appealing.

For wines with a high turnover, synthetic closures and screwcaps can be a more economically appealing solution. They are often used in markets such as New Zealand, Australia and the UK and have in common the fact that they alter the evolution of the wine and are not recommended for prolonged ageing.

Synthetic stoppers don't seal the bottle completely and can cause post-bottling oxidation due to excessive O2 entering the bottle. This phenomenon is associated with early evolution of aromas. Saran screwcaps, on the other hand, completely seal out O2, promoting reactions that produce sulphides, giving rise to very unpleasant aromas, such as rotten eggs. The main disadvantages of glass closures are their high price and their vulnerability to damage during transportation, and in the evolution of wines they perform similarly to plastics.

Natural cork stoppers continue to be essential and maintain their prominent position in the preservation of quality wines, as they promote their balanced evolution. However, faced with the problems associated with sensory deviations caused by cork stoppers and growing competition, the cork industry has focused its attention on manufacturing increasingly efficient stoppers and eradicating the problem of TCA.

Natural corks Colmated

Natural corks Colmated Technical corks

Technical corks Champagne corks

Champagne corks Aglomerated corks

Aglomerated corks Tapered corks

Tapered corks